-

Suitable for use in continuous production lines

-

RoHS and REACH compliant

-

Outperforms industry standards

-

Increased durability

-

Protected against white rust

-

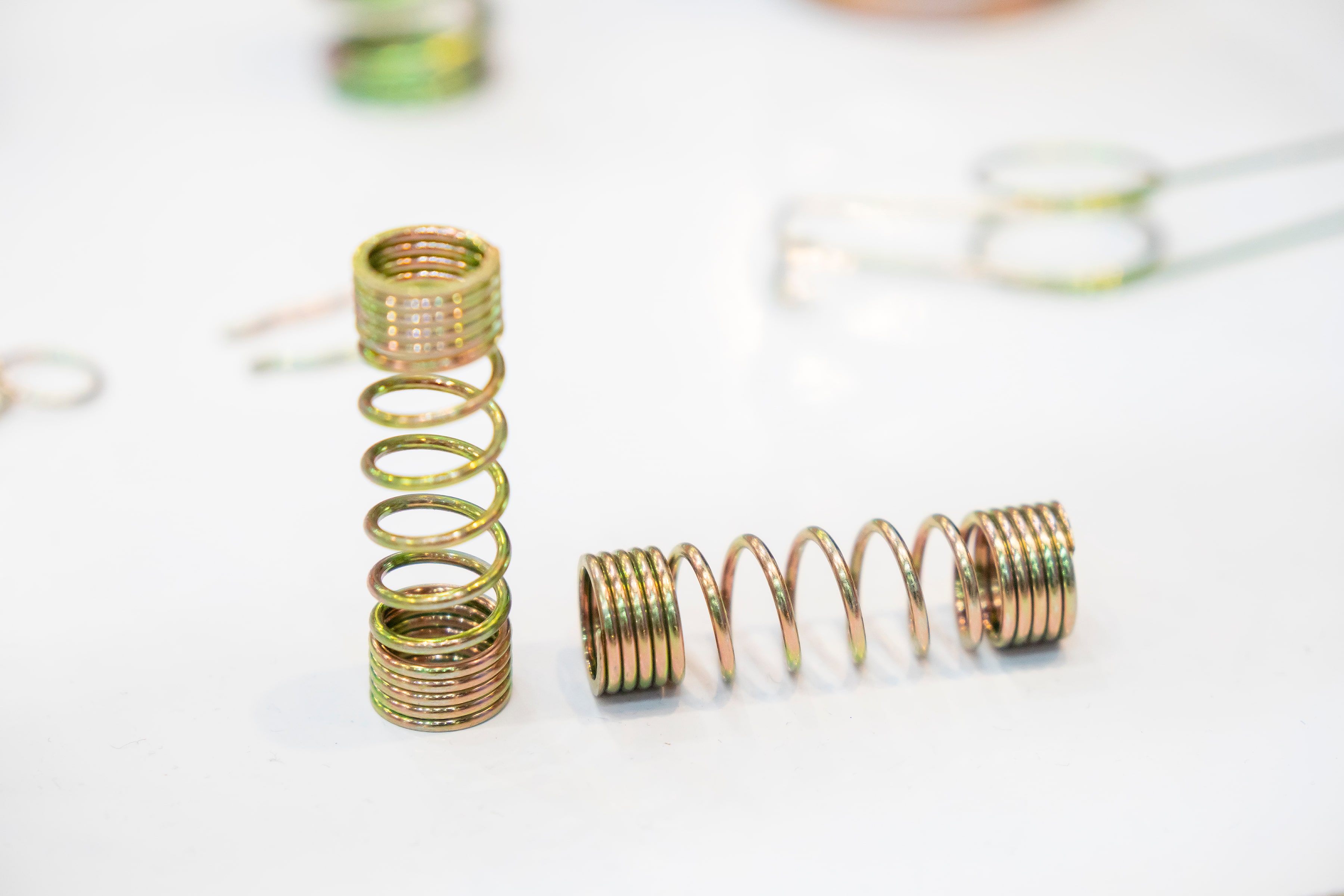

Transparent and colored passivation

Solutions for in-line passivation of galvanized tubes and wires, offering corrosion protection and reliable coating adhesion. Designed for high-speed continuous processing lines.

Galvanized steel tubes and wire products are widely used in industries where mechanical strength, corrosion resistance, and surface quality are essential. AD Metal Surface Treatment offers a complete product portfolio for the chemical surface treatment of continuously galvanized tubes and wire, specifically developed for in-line application in automated production lines.

Our portfolio includes:

- Adhesion promoters

- Passivation solutions

Adhesion promoters

For applications involving organic coatings, our adhesion promoters enhance the bonding between the galvanized surface and the coating system. They provide:

- Increased coating durability

- Improved edge coverage

- Reduced risk of delamination or flaking

These products are compatible with various coating technologies and can be applied directly after the galvanizing process in continuous production lines.

Passivation for zinc protection

For uncoated applications or temporary protection, our passivation solutions form a transparent or lightly tinted conversion layer that significantly increases the corrosion resistance of the galvanized surface.

Key benefits of our passivation solutions:

- Effectively prevents the formation of white rust

- Extends product lifespan during storage, transport, and use

- Suitable for fast, in-line processing in continuous operations

We offer both transparent and coloured passivations. Coloured variants (such as blue, iridescent, or yellowish tones) can serve functional or aesthetic purposes, such as product identification, branding, or improved corrosion performance.

Our passivation technologies are available as Chromium(III)-based or completely chromium-free formulations, depending on your environmental and performance requirements. All variants are designed for consistent results and full compatibility with automated processing lines.

The galvanized surface of tubes and wire products is passivated to provide additional protection against the formation of unwanted white rust. This passivation enhances the service life and reliability of the product – even in demanding environments or outdoor applications.

Need advice for your production line?

Our technical experts are ready to assist you in selecting the optimal solution for your application.

Discover more

Passivation

‘White rust’ the enemy of zinc coated steel strips, is in itself a form of corrosion that occurs during storage and is unacceptable for critical applications in, white goods, construction and other industries.

Pre-treatment

Durability and extended end-use life are demands that consumers take for granted and of which they expect continuous improvement year on year. Paint adhesion and corrosion resistance are critical factors in keeping end-use applications in a condition that is expected to remain in place for their usable life time.

Thin Organic Coatings (TOC’s)

Thin Organic Coatings (TOC’s) are applied in a continuous process to hot dip galvanized steel strip and other metal substrates, and can offer a wide range of benefits from anti-fingerprinting to improving, forming and enabling enhanced corrosion protection.

Cleaners and specialty additives

Oils and greases used during processing as well as other forms of surface contamination must be removed. This can be achieved using either acid or alkaline based cleaners depending on the nature of the contamination and the type of metal substrate.

Lubricant boosters

During the processing of metal sheets, lubricant enhancers play a crucial role in reducing wear and tool contamination. They optimize the production process and extend the service life of tools.

✔ Less tool wear

✔ Less maintenance and downtime

✔ Improved product quality