Thinking ahead in a changing landscape: Sustainable paint stripping without methylene chloride and working without solvents.

The surface treatment industry is at a tipping point. Stricter legislation, such as the REACH regulation, is forcing companies to critically review their processes and materials. Substances such as methylene chloride (DCM) and volatile organic compounds (VOCs) are coming under increasing pressure. Thinking ahead is no longer an option – it is a prerequisite for ensuring production reliability, safety and sustainability.

Legislation as a wake-up call

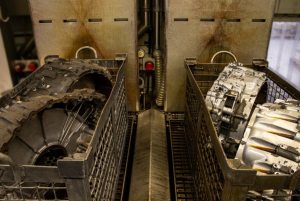

Strict rules on the use of methylene chloride in paint stripping have been in place in the EU for many years. Under REACH (EC) No. 1907/2006 and national environmental legislation, its use in consumer and professional applications has been banned since 2010. Only industrial applications in fully enclosed systems, where vapours are controlled and exposure is minimal, are still permitted.

A total ban is expected to be only a matter of time. Those who do not anticipate this now will soon run the risk of production stoppages, higher costs or even legal consequences. That is why it is important to switch to safe and effective alternatives in good time.